Introduction

ACRI-BOND Methacrylate Adhesives are high-performance structural adhesives used across a wide range of industries. From signage and plastic fabrication to automotive, transportation and marine. MMA (methyl methacrylate) adhesives are suitable for their excellent bond strength, substantial elongation, fast cure times and versatility with difficult substrates.

We know the wide range of methacrylate adhesives can be a bit overwhelming, but we’re here to explain each option for you and help you find the right fit for your application. Thats why we have prepared this guide to methacrylate adhesives.

Why It Is Important to Choose the Correct MMA Adhesive

Choosing the right adhesive for your application is important. While many MMA adhesives can be used interchangeably, certain applications will perform better with specific formulations. Whether you need a faster cure time to speed up production or a thick, no-drip viscosity for vertical or overhead bonding, we offer a wide range of options to suit your needs.

We will run you through the options of our Methacrylate Adhesives below to help you choose the right one for your application.

You can view all of our options here. But be sure to read the guide to also learn how to choose the correct MMA Adhesive and what all the options mean.

What Is the Primary Use of the Adhesive?

Each ACRI-BOND MMA Adhesive is designed for a primary purpose, it is important to start here if you need something specific. Most cases an all-purpose MMA adhesive is suitable, but some applications may require high strength metal bonding or clear variations or polyolefin bonding.

All Purpose: These formulations offer a strong balanced strength, there are many variations in working time and fixture time as well as multiple different viscosities perfect for most bonding tasks. ACRI-BOND 200 and ACRI-BOND 210 would fall under this category.

Polyolefin Bonding: Specifically designed for structurally bonding low surface energy plastics such as polypropylene and polyethylene (including both HDPE and LDPE), which are notoriously difficult to bond using conventional adhesives. ACRI-BOND 206 is our specialised polyolefin bonder.

High Strength Metal Bonding: Some metal-to-metal and metal-to-composite applications require higher tensile and shear strength, which is why we offer a dedicated high-strength metal bonding MMA range. This range is specifically formulated for demanding structural bonds and is separate from our all-purpose MMA adhesives. Within this category, we provide multiple options for working time and viscosity so you can choose the best fit for your exact application requirements. ACRI-BOND 230 is one of our high strength metal bonding adhesives.

Clear or Crystal Clear Variants: Ideal for applications where appearance matters but strength is also a concern, such as large acrylic displays, aquariums and signage (standard and channel signage). ACRI-BOND 204 and ACRI-BOND 290 are our clear variants.

Working Time

Working time is the period after the adhesive is dispensed and mixed during which you can position and press the parts together before it begins to set. It is important to complete positioning and assembly within this time because once the adhesive begins to harden, a tough surface layer can form, preventing proper bonding and reducing overall strength. The parts should be clamped before the working time is over and until fixture time is complete.

ACRI-BOND MMAs range from ultra-fast 4–6 minute working times up to 80-100 minutes for complex assemblies. Choose a faster working time for a high-volume production line where speed matters most or a slower one if alignment and clamping take longer. The working times are measured at 25°C a lower temperature will result in a slower working time, a higher temperature will result in a faster working time.

Fixture Time

Fixture time is the point at which the adhesive has developed enough strength to be handled, typically reaching around 60 to 80 percent of its final strength. At this stage, clamps can be removed, and parts can be moved or processed, but the bond is not yet strong enough to withstand full mechanical loads. This is especially important in production environments where parts need to be moved or processed quickly.

A fast fixture time can significantly improve output, but make sure you can work within the working time. As a general rule, the shorter the working time, the quicker the fixture time. The fixture times are measured at 25°C a lower temperature will result in a slower fixture time, a higher temperature will result in a faster fixture time.

Viscosity

Viscosity determines how thick or runny the adhesive is. Thicker products (high viscosity) are less likely to slump or drip, making them suitable for vertical applications or large gaps. Thinner versions (low to medium viscosity) have a better flow to them making them ideal for applications where the adhesive needs to spread evenly across the bonding surface or fill narrow gaps.

Our MMA Adhesives start at a viscosity of 10,000 CPS and go up to around 200,000 CPS.

We have made a viscosity chart here comparing everyday consumer goods and their CPS, so you can easily visualise the different CPS of all our adhesives.

Gap Fill

ACRI-BOND MMA adhesives have excellent gap-filling abilities. Some grades can fill gaps up to 30mm. This makes them ideal for bonding irregular or imperfectly fitting surfaces. The gap filling capacity is generally directly related to the adhesives viscosity a thicker viscosity will result in a better gap filling capacity.

Mixed Colour

ACRI-BOND Methacrylate Adhesives typically have a base colour when mixed (commonly off-white, grey or beige). We also have two clear variants, one clear for metal, plastic and composite bonding and another crystal clear for plastic and composite bonding. For high-volume users, we can tint the mixed colour to suit your requirements, including black or neutral shades that blend into the substrate. Just ask us for custom options.

Mix Ratio

Mix ratio determines how the two adhesive components are dispensed. The most common being a 1:1 (1 Part Resin to 1 Part Hardener) or 10:1 mix ratio (10 Parts Resin to 1 Part Hardener).

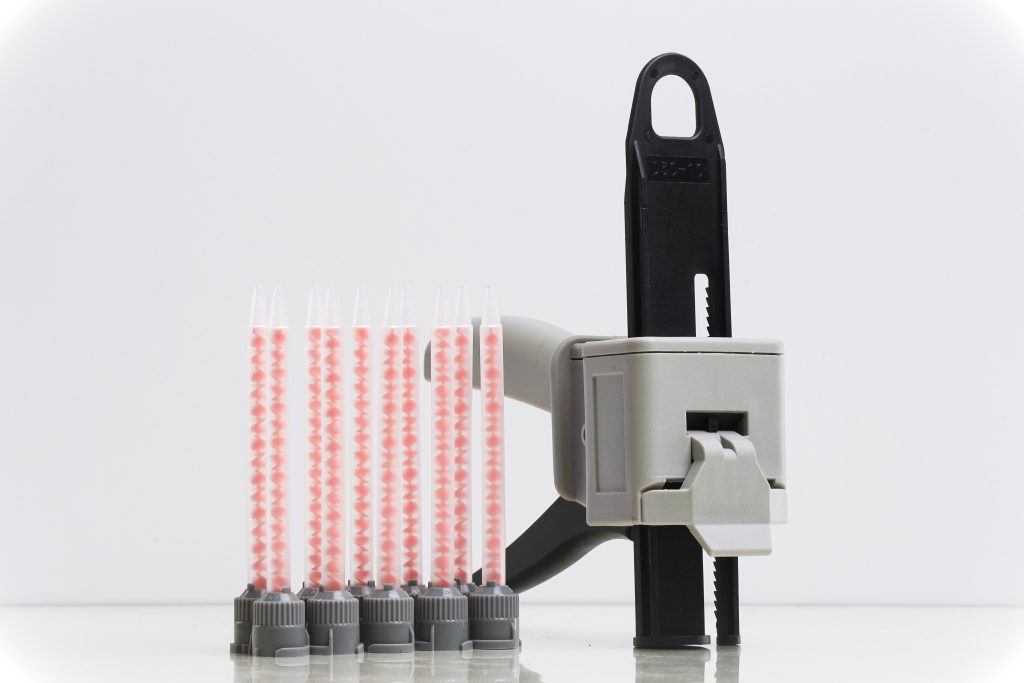

Make sure your equipment is compatible, as each mix ratio requires a specific type of static mixer. For example, a 10:1 cartridge uses a different static mixer than a 1:1 cartridge. The same applies to the applicator guns, a gun designed for 1:1 cartridges will not work with 10:1 cartridges and vice versa. Static mixers and applicator guns are not universal; they are matched to the specific cartridge type and ratio.

We stock the correct equipment on our website, including a full range of static mixers and applicator guns tailored for each mix ratio. Whether you’re using 1:1 or 10:1, we have the right tools to ensure proper dispensing and mixing. All our accessories are tested for compatibility with our adhesive cartridges to help you avoid application issues, waste or costly rework. If you’re unsure which equipment suits your adhesive, our team is here to help you choose the right option for your setup.

Operating Temperature

ACRI-BOND MMA Adhesives can handle a wide range of operating temperatures. Most are stable between -40°C and +140°C, though some high-temp variants can push higher. Our adhesives can be exposed to higher temperatures for short amounts of time provided the joint is not stressed within this period. This range of temperatures makes the adhesives suitable for a large variety of applications.

So What’s Next?

Choosing the correct ACRI-BOND MMA adhesive comes down to understanding the demands of your application and matching them to key product attributes. If you’re unsure, reach out with the details of your job. We’re happy to recommend the best option, assist with sampling, or help you optimise your bonding process. Whether you’re after speed, strength, a certain viscosity or clarity there’s an ACRI-BOND Adhesive that fits the application.