What Are Methacrylate Adhesives?

Methacrylate adhesives, often called Methyl Methacrylate Adhesives (MMA Adhesives), are high-performance structural adhesives used to bond a wide variety of materials. These adhesives come in two parts that react when mixed, creating a strong, durable bond. Unlike traditional glues, they form chemical bonds with plastics, composites and metals, making them incredibly versatile. They are widely used in industries where strength, speed and flexibility matter.

How Do Methacrylate Adhesives Work?

MMA adhesives cure through a free-radical polymerisation process. When the two components (resin and catalyst) are combined, they start a controlled chemical reaction. This creates heat (an exothermic reaction) and causes the adhesive to solidify quickly. The bond formed is both chemical and mechanical, giving methacrylates their signature strength and shock resistance.

Key Benefits of Using MMA Adhesives

Methacrylate adhesives offer a combination of properties that make them stand out from other adhesive types:

- Bond dissimilar materials like metal to plastic or composites

- Excellent impact resistance and peel strength for demanding applications

- Rapid cure time at room temperature to increase industrial productivity

- Gap-filling ability to accommodate irregular surfaces or high tolerence fits

- Minimal surface preparation compared to epoxies or polyurethanes

- Good environmental resistance including temperature swings, vibration and chemical resistance

These features make MMA adhesives ideal for applications where traditional adhesives fail.

Common Applications and Industries

Methacrylate adhesives are used across many industries thanks to their versatility. Some uses include:

- Signage and displays – bonding acrylic panels, frames, and metal supports

- Automotive and transport – attaching panels, brackets, metal bonding

- Marine – bonding fibreglass, composite materials

- Metal fabrication – joining aluminium, steel or powder-coated parts

- Plastic fabrication – joining ABS, acrylic, PVC or polycarbonate

Whether you’re a large manufacturer or a small workshop, MMAs are a go-to option where a structural, permanent bond is needed.

Surfaces and Materials You Can Bond

MMA adhesives are especially known for their ability to bond:

- Plastics like acrylic, ABS, polycarbonate, PVC, ASA

- Metals including aluminium, steel, stainless steel and powder-coated surfaces

- Fibreglass, carbon fibre, and composite panels

They even work on some challenging substrates. ACRI-BOND 206 will structurally bond very low surface energy plastics like polypropylene (PP) or polyethylene (PE).

MMA Adhesives vs Other Technologies

If you’re choosing between adhesives, here’s how methacrylates stack up:

Epoxy Adhesives

Methacrylate adhesives offer greater flexibility and toughness compared to epoxies, making them less brittle and less likely to crack under impact or vibration. They also tolerate slight mix inaccuracies better and are generally easier to use in fast-paced environments. MMAs can fill large gaps, cure quickly or slowly depending on the formulation, and bond a wider range of materials including many plastics that epoxies struggle with.

Polyurethane Adhesives

MMA adhesives offer higher bond strength on a broader range of materials, especially plastics and metals. While polyurethanes have good impact resistance and gap-filling ability, MMAs cure faster and are generally less sensitive to moisture or surface contamination. Both provide strong environmental resistance, but MMAs deliver better long-term durability and require no primers or surface treatments, making them more efficient in demanding applications. They are also the health conscious choice as polyurethanes have been linked to various health concerns.

Mechanical Fastners

Methacrylate adhesives offer strong, more durable bonds that distribute stress evenly and eliminate the need for mechanical fasteners (which can loosen/fail with time). They reduce labour, lower weight, resist corrosion, fill gaps easily and provide a cleaner, more professional finish.

Welding

Methacrylate adhesives are a cost-effective solution that require no post-finishing, saving both time and money. They bond dissimilar materials with ease, are simple to use, reduce labour and increase productivity. With no risk of corrosion or heat distortion, they deliver a clean, professional finish and can even bond in hard-to-reach areas.

Cyanoacrylates (super glues/ instant adhesives)

MMAs have much better durability and gap-filling properties. Superglue is fast but not ideal for long-term load-bearing bonds.

Solvent cements

MMAs can bond a much wider range of materials, whereas solvent cements are mostly limited to similar or same substrates to themselves.

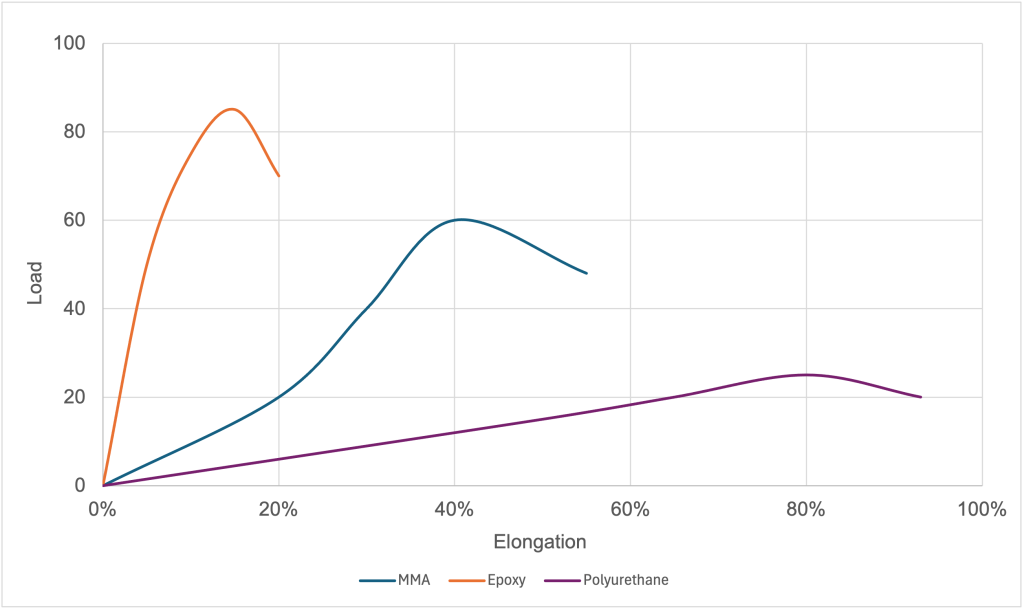

The graph above illustrates how methacrylate adhesives strike a balance between the high strength of epoxies and the flexibility of polyurethanes. They combine the best features of both, offering strong, durable bonds with excellent impact resistance and elongation.

Some Popular ACRI-BOND Methacrylate Adhesives

1. ACRI-BOND 210 – All-Purpose MMA Adhesive bonds plastics, metals and composites.

2. ACRI-BOND 290 – Crystal Clear MMA Adhesive Plastic and Composite Bonder

3. ACRI-BOND 206 – Structural MMA Adhesive for Polyolefin Bonding

4. ACRI-BOND 204 – Clear MMA Adhesive that bonds plastics, metals and composites.

Tips for Using Methacrylate Adhesives Effectively

To get the best results from methacrylate adhesives:

- Clean the surfaces with ACRI-BOND CLEANER or use ACRI-BOND Surface Adhesion Promoter (SAP) for extra bonding strength on metals.

- Use the correct mix ratio, through a static mixing nozzle and using a static mixing dispenser. Failure to do this will result in disproportionate mix ratios and may affect bond strength.

- Apply within the working time different times apply to each formula check technical data sheets for info.

- Clamp parts together until the fixture time is reached. Different times apply to each formula check technical data sheets for info.

- Ensure good ventilation. MMA adhesives have a strong smell and should be used with proper PPE

- Some products cure quickly, while others offer extended working time for larger or more complex assemblies choose one that suits your needs. We will be going over choosing the correct MMA adhesive next.

Are Methacrylate Adhesives Right for You?

If you’re working with plastics, metals or composites and need a reliable structural bond, methacrylate adhesives are likely the right choice. They’re easy to use, require minimal prep and deliver long-term performance in tough conditions. Whether you’re in signage, auto repair, fabrication or general industrial assembly, these adhesives can reduce labour and increase reliability.

Ready to make the switch?

Methacrylate adhesives strike a balance between speed, strength and versatility. If you’re tired of glues that peel, crack or fail under stress, switching to an MMA adhesive can make a major difference. If you’re not sure which product suits your job, reach out. We’re happy to help match the right adhesive to your materials and application.