Applications

ACRIFIX 192 is preferably for transparent edge and area bonds of clear acrylics, i.e. PLEXIGLAS GS, PLEXIGLAS XT and parts made of PLEXIGLAS moulding compound, but also for other clear plastics such as CAB, PC and PS.

Typical Values of ACRIFIX 192

Viscosity; Brookfield II/12/20°C: 1800±200 mPa • s.

Density/20°C: ~ 1.02 g/cm3.

Refractive index nD20: ~ 1.44.

Colour: clear, slightly purple.

Flash point DIN 53213: ~ 10°C.

Solids content: 32 ± 2%.

Storage stability: 2 years after filling, if correctly stored.

Curing System:

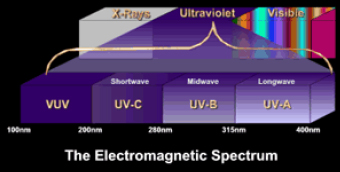

ACRIFIX 192 is Polymerized by UV light

UV Light source / Curing period (at 25°C)

- Fluorescent lamp, illuminant 25, 15 to 30 min.

- Super actinic UV-A fluorescent lamp, e.g. Philips TL …/05, 10 to 15 min.

- Tanning studio UV-A fluorescent lamp, e.g. Philips TL …/09, 10 to 15 min.

- Diffuse ambient lighting, illuminant 25, 1.5 to 3 hrs.

- Sunlight, 10 to 20 min.

Pot life:

200 g in glass vessel exposed to diffused ambient lighting ˜30 min (at 25°C).

Preparing the Parts to Be Bonded

Degrease the surfaces to be bonded with water containing a wetting agent (washing- up liquid), or with THINNER AND CLEANER 30. Internally stressed parts must be annealed before bonding in order to avoid stress cracking.

The annealing conditions depend on the type of material, the degree of forming and the thickness of the parts to be bonded. Parts made of extruded and injection-moulded acrylic should be annealed as a matter of principle. Typical annealing times – also for cast acrylic – are 2 to 4 hours in an airflow oven at 70 to 80°C. If annealing is not possible, we recommend the use of ACRIFIX 106 or ACRIFIX 107 (only for commercial use). These presuppose that the surfaces to be bonded are flat and without V grooves or superimposed layers.

Other Measures

Roughening-up with abrasive paper (grit 230 to 320) improves the adhesion to untreated surfaces of cast acrylic. Severely stressed bonds or those intended for outdoor exposure should be annealed for 2 to 4 hours at 70 to 80C immediately after curing. ACRIFIX 192 must not get into closed cavities (e.g. double glazing, tube interiors), since the curing process is severely hampered at such sites, and there is a risk of stress cracking in the bonded parts.

Properties of Bonds

Further treatment of bonded parts: 2 to 6 hours after curing, sanding and polishing after 24 hours.

Tensile shear strength (v = 5 mm/min):

| Material (to itself; cured with illuminant 25) | non-annealed | annealed |

| PLEXlGLAS® GS 233: | 28 ± 5 MPa | 48 ± 5 MPa |

| PLEXlGLAS® XT 20070: | 32 ± MPa | 50 ± 5 MPa |

Material (to itself; non-annealed annealed cured with illuminant 25 )

PLEXlGLAS® GS 233: 28±5 MPa 48±5 MPa

PLEXlGLAS® XT 20070: 32±MPa 50±5 MPa

Bonding Technique

Fix the parts to be bonded in the desired position (avoid shading) and apply suitable adhesive tape to the joint and to protect surrounding areas (see drawings). Introduce ACRIFIX 192 into the joint either directly from the tube or by means of a glue dispenser or disposable syringe, avoiding bubble formation. Then expose the joined parts to a suitable light source (see Curing). For this, “ordinary” fluorescent lamps of illuminant type 25 are to be preferred, since they provide optimal curing of ACRIFIX 192 and require no special protective measures against UV radiation at the workplace.

Appearance: Clear, almost colorless; surface may be slightly yellowish.