Product Overview

ACRI-BOND 105 is a very fast curing water thin, clear solvent cement ideal for joining cast and extruded acrylic, polycarbonate, ABS and more. It provides almost instant initial bonding which makes it ideal for producing butt joints, t joints and mitre joints. It is great for production lines working with acrylic as it is fast and easy to use once you understand the technique to using it.

Due to being a water thin solution, this acrylic glue is drawn into joints by a capillary effect. This means you can position your acrylic parts first, then apply adhesive to the edge. The adhesive will wick into the joint, ensuring an even distribution and minimal mess. This is how all the professional acrylic fabrication shops glue acrylic.

If you are finding bubbles and white hazing appearing when using a competitor’s product, try using ACRI-BOND 105 as it is specially formulated to reduce this. These issues occur when the adhesive cures too fast or creates an air pocket in the joint. For true bubble free joining for indoor use consider our ACRI-BOND UV Adhesives.

To learn more about how to use a water thin adhesive like ACRI-BOND 105 read our guide here.

Applications and Uses

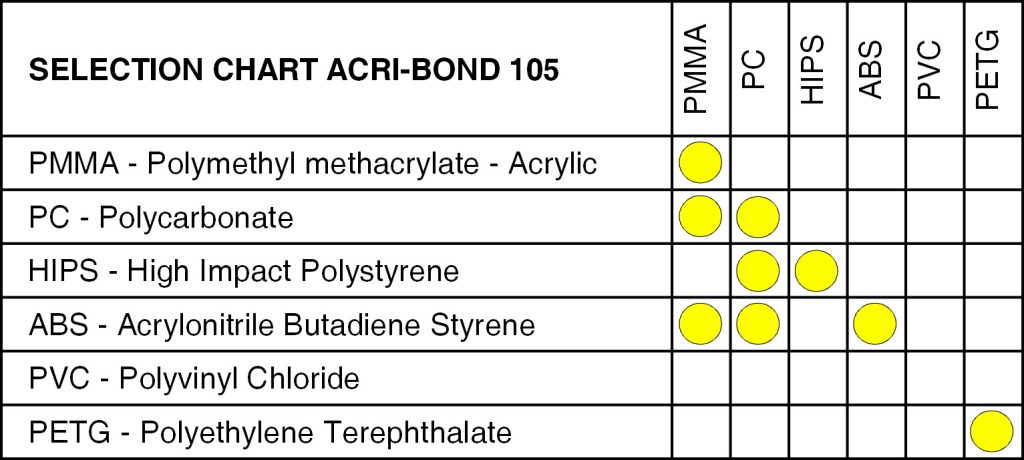

ACRI-BOND 105 has been designed for bonding Acrylic to Acrylic. It also shows good results when bonding Polycarbonate, HIPS, ABS and PETG to themselves. If your substrate is not listed in our material suitability tab due to it being mixed or other plastic material combinations, contact us or test on a small job before using in your production.

It can be used in a range of plastic fabrication jobs. For example: Sign Fabrication, Display Boxes, Plastic Structures, Model Making and Point of Sale Displays.

Tools and Accessories

For professional use of ACRI-BOND 105 it is important to use the right tooling. We recommend using our 65mL Applicator Bottle with either a 0.5mm (blue base) or 0.6mm (pink base) precision dispensing tip. This will allow for maximum control of the adhesive when applicating.

To help dispense the adhesive into the applicator bottles we stock small clear funnels and clear 100mL beakers.

Technical Highlights

| Key Substrates | Acrylic, PC, HIPS, ABS, PETG |

|---|---|

| Colour | Clear / Transparent |

| Viscosity | 1 – 5 CPS |

| Fixture Time | 3 min |

| Strength | High |

| Initial Tack | < 30 sec |

| Full Cure | 24 hrs |

| Pack Size | 100mL, 500mL, 4L |

Instructions for Use

Parts to be joined should fit without forcing and be clean, it is recommended to use Acri-Bond Cleaner prior to applying any product to remove any dust and dirt. To maximise its strength and the final products clarity it is recommended you sand your saw cut edges if they are rough as this product does not have a high gap filling capacity and they may be seen. Apply adhesive with suitable applicator and assemble while parts are still wet. Press parts together in firm contact. ACRI-BOND 105 forms an initial bond very quickly. Strength develops rapidly reaching full strength in 24 to 48 hours leaving no dry residue. For a tutorial how to use please refer to our YouTube Chanel.

Shelf Life and Storage

ACRI-BOND 105 has a 2+ Year Shelf Life when stored correctly.

Store in a cool dry place out of direct sunlight to extend the shelf life of this product. Keep the open container tightly closed do not leave open as the adhesive will evaporate.